Nittobo Group strives to contribute to the realization of an enriched society,

serves as a valued corporate group in society, and commits to the creation of comfortable life.

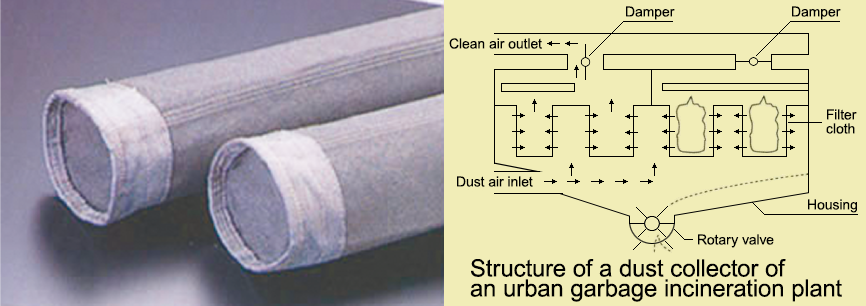

For filter bags

Nittobo's glass filter bags excel in heat resistance, corrosion resistance, and chemical stability compared to other synthetic fiber bags.

Filter bags are used to prevent pollution, improve labor environment, and collect valuable powder discharged from cement, chemicals, and other factories. The filter cloth, the heart of the filter bag, is required to be less costly and collect dust efficiently.

In particular, glass filter bags excel in heat resistance, corrosion resistance, and chemical stability compared to other synthetic fiber bags.

Various methods of weaving and treatment are used for Text Glass™ filter bag cloth to meet diverse customer requests.

Typical treatment methods

| Treatment name | Characteristics of treatment |

|---|---|

| TRITEMP™2 | This is the most widely used treatment method. Even in a high-temperature gas environment, 1. It is flexible and can be used continuously. 2. It improves dust detachability. |

| ST-4A | This treatment increases resistance to acids and chemicals. |

Characteristics of various types of filter cloth

| Item Materials |

Characteristics of fibers | Characteristics of filter cloth | ||||

|---|---|---|---|---|---|---|

| Tensile strength (g/d) |

Elongation percentage (%) |

Specific gravity (-) |

Acid resistance |

Alkali resistance |

Maximum temperature for use |

|

| E glass | 4.0 ~ 5.5 | 3 ~ 4 | 2.54 | ○ | ○ | 280℃ |

| Teflon | 1.0 ~ 2.5 | 25 ~ 50 | 2.1 | ◎ | ◎ | 250℃ |

| Aramid | 4.5 ~ 5.5 | 35 ~ 50 | 1.38 | △ | ○ | 200℃ |

| Polyester | 4.3 ~ 6.0 | 20 ~ 32 | 1.38 | ○ | △ | 140℃ |

| Acryl | 3.2 ~ 5.0 | 12 ~ 20 | 1.14 | △ | ○ | 140℃ |

| Nylon 6.6 | 5.3 ~ 6.4 | 28 ~ 38 | 1.14 | × | ○ | 140℃ |

- * The values listed above indicate reference ones at standard times, and are not guaranteed ones.

Specifications (standard)

| Product code | Manner of weaving | Thickness mm |

Width mm |

Weight g/m² |

Density (/25mm) |

Tensile strength (N/25mm) |

Length m |

Ventilation rate cm³/cm² /sec |

||

|---|---|---|---|---|---|---|---|---|---|---|

| Warp | Weft | Warp | Weft | |||||||

| KS4155/ TRITEMP™2 |

Twill | 0.42 | 965 | 485 | 41 | 30 | >2400 | >2400 | 100 | 32.0 |

| KS4325/ ST-4A |

Double | 0.85 | 1170 | 880 | 48 | 48 | >2200 | >1700 | 61.5 | 10.0 |

- Business introduction

- Glass Fiber

- What is glass fiber?

- Special materials

- Composite materials

- Yarn

- High-performance glass cloth

- Industrial materials

Interior furnishings market

Market for exterior furnishings

Construction market

Lifestyle, sports, and leisure markets

Media market

Automobile and aircraft markets

Heat resistance and heat insulation markets

Civil engineering market

Market for industrial base materials

- Medical

- Textile