Nittobo Group strives to contribute to the realization of an enriched society,

serves as a valued corporate group in society, and commits to the creation of comfortable life.

Glass Fiber

Nittobo continues to be the frontrunner in the field of glass fiber manufacturing

Its glass fiber business will stay ahead of the pack by exploring the infinite possibilities of the product.

The Nittobo Group is Japan's first industrial manufacturer of glass fiber. Today, Nittobo's glass fiber business is vertically integrated from filament production through glass fabric processing to composites development, supplying a wide spectrum of customers with high-quality products. One example is the ultra-thin glass cloth made by weaving glass fabric of several microns thickness, which has found use as precision material for PCs, smartphones, and other electronics that are becoming increasingly small, lightweight, and functional. Its quality has garnered high praise around the world.

In the glass wool sector as well, Nittobo boasts its high proprietary technology as a pioneer in heat insulation materials. In particular, its high-performance glass wool has contributed to the creation of an energy-saving society, being used in airtight and heat-insulated residential buildings.

Typical examples of use

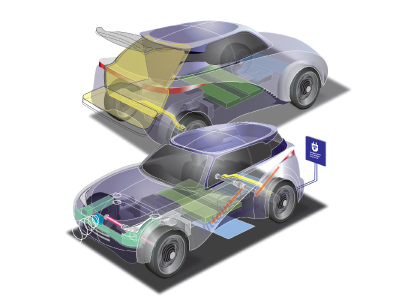

Automobiles

Beyond weight reduction

As lightweight, high-strength material, fiber-reinforced plastic (FRP) is widely used in various automotive components.

Characterized by not only high shape stability and ease of processing but also high resistance to impact and heat, Nittobo's glass fiber offers new value to automobiles as they evolve toward electrification and high driving support.

Composites for smartphone casings (FF)

Realizing molded products that are not easily distorted despite their thinness

Flat fiber (FF), which is produced by using Nittobo's own technology to make glass fiber cross section not circular as it usually is but oval, prevents molded products from being warped or twisted when used as composites. It is employed for the casing of small electronic devices such as smartphones, which do not tolerate even the slightest distortion.

High performance electronic substrates

Supporting the evolution of smartphones

The Nittobo Group's ultra-thin glass cloth, which excels in insulation, heat resistance, and dimensional stability, is used mainly as the insulation layer of electronic substrates. Its thin, uniform fabric distribution contributes to making electronic equipment even smaller and more High performance.

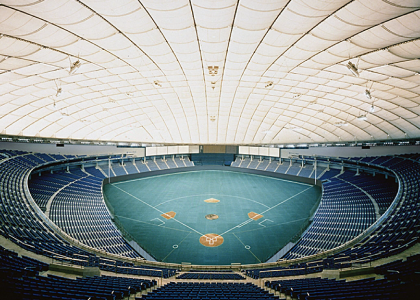

Resin-coated film materials

Used for the ceiling of Tokyo Dome

Glass cloth for film materials, which is produced using ultra-thin glass fiber, is used for indoor tennis courts, tent-type warehouses, various kinds of events, as well as multi-purpose stadiums, soccer grounds, and other facilities.

House insulation materials (glass wool)

Realizing high heat insulation and airtight houses

Glass wool displays high insulation performance. It also excels in airtightness and soundproofing and is used for a wide range of purposes from structures such as houses and buildings to vessels and vehicles. For housing purposes, it has further enhanced its performance by using thinner fibers, thus contributing to an energy-saving society.

Nittobo's products

- For composite materials

-

- Roving

- Chopped strand

- General-purpose chopped strand

- Modified cross-section chopped strand

- General-purpose chopped strand

- Mat

- Roving cloth

- Cut fiber

- Roving

- Yarn

- Glass cloth for electronic materials

- Industrial materials

- Glass wool

- Business introduction

- Glass Fiber

- What is glass fiber?

- Special materials

- Composite materials

- Yarn

- High-performance glass cloth

- Industrial materials

Interior furnishings market

Market for exterior furnishings

Construction market

Lifestyle, sports, and leisure markets

Media market

Automobile and aircraft markets

Heat resistance and heat insulation markets

Civil engineering market

Market for industrial base materials

- Medical

- Textile